還沒有賬號(hào)立即注冊(cè)

登錄即代表您已同意《廣州賽意信息科技股份有限公司隱私政策》

登錄即代表您已同意《廣州賽意信息科技股份有限公司隱私政策》

已有賬號(hào)登錄賬號(hào)

Provide high-quality event services to fully support digital upgrades

SiE布局新基建“5G+工業(yè)互聯(lián)網(wǎng)”

Layout of New Infrastructure: Typical Scenarios and Case Analysis of 5G+Industrial Internet

The industrial internet is a key support for the fourth industrial revolution, and 5G is an important direction for the evolution and upgrading of the new generation of information and communication technology. Both are important driving forces for achieving digital transformation of the economy and society. The integration and innovative development of 5G and industrial internet will promote the transformation of manufacturing industry from single point and local information technology applications to digitalization, networking, and intelligence, thus moving towards the goal of building a strong manufacturing and network power.

In order to accelerate the implementation of the "5G+Industrial Internet" 512 project and promote high-quality integration and innovation between 5G and industrial Internet, the country has made it clear that by 2022, it will break through a batch of 5G key technologies that meet the specific needs of industrial Internet, and the industrial support capacity of "5G+Industrial Internet" will significantly improve; Build 5 industrial public service platforms, build innovative carriers and public service capabilities; Accelerate the leading application of "5G+Industrial Internet" in the vertical field, and cover 10 key industries through internal network construction and transformation; Create a batch of benchmark and model projects for the construction and transformation of the "5G+Industrial Internet" intranet, forming at least 20 typical industrial application scenarios; Cultivate an innovative trend of integrating and overlapping 5G with the industrial internet, promoting mutual progress and doubling development, promoting the digitalization, networking, and intelligent upgrading of the manufacturing industry, and promoting high-quality economic development.

The development of industrial Internet is inseparable from the comprehensive innovation and exploration of network, logo, platform and security. On the network side, OPC UA+TSN is the consensus of the industry, and the combination of 5G and edge computing has become the new exploration direction of industrial Internet; The application of identification in industrial internet will be systematized, and distributed architecture will become a new hotspot; The Internet platform has achieved deep collaboration between the edge and cloud, and application innovation support has become a key focus for improvement; Security testing, security authentication, and data security have become research focuses.

From today's perspective, many new models and formats have emerged in the industrial internet field, stimulating the vitality of manufacturing industry transformation and upgrading. Next, the integration of 5G+industrial internet will have a multiplier effect, helping many enterprises achieve remote collaborative management, product service-oriented, real-time supply and demand docking, intelligent production and refined control, and unmanned. SiE Information is committed to the development of industrial internet, new generation information technology, and digital transformation, and can provide corresponding strategic solutions for enterprise level customers.

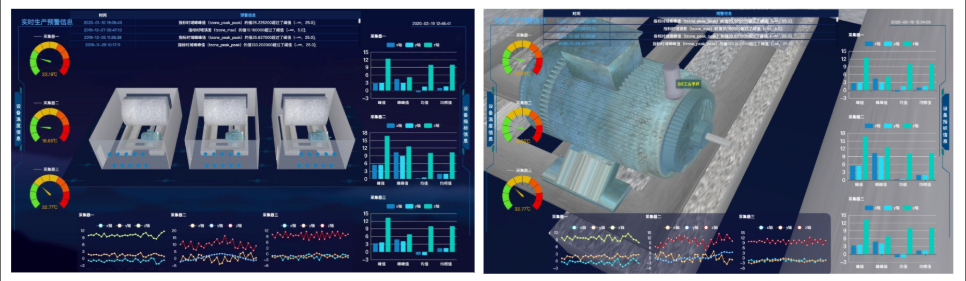

1. Remote monitoring and health management of devices (application core: 5G data transmission and data collection)

In traditional production environments, equipment is prone to "working with defects" due to a lack of health management and effective monitoring, resulting in low product yield and severe wear and tear. At the same time, sudden unplanned downtime of equipment and delayed procurement and turnover of spare parts can also bring significant losses to production. However, traditional production factories also face problems such as complex production environments, multiple special environmental requirements, multiple mobile devices, difficulty in laying data transmission equipment lines, and high costs. In addition, the production equipment monitoring system needs to be adjusted frequently based on production tasks and in conjunction with production lines, so using wired networking is extremely complex and has a long construction period. However, relying on traditional network technology, it is difficult to ensure the real-time requirements of industrial data collection. Traditional data collection technology is difficult to ensure the real-time collection and upload of important information for high-precision and low latency industrial scenarios, and cannot meet the real-time monitoring requirements of the production process.

Through 5G network technology, it features ultra high bandwidth (10-20Gbps), wide connectivity (1 million), low latency (1ms), high reliability (99.999%), flexible mobility, and high security. It uses mobile edge computing to solve the problems of multi device access and protocol conversion, and can easily achieve efficient and stable transmission of operating status data of multiple groups or even massive production equipment to the cloud platform for analysis and diagnosis combined with algorithms, Transmit device status and health diagnosis results to multiple ports of customers, real-time grasp of device faults and health status, easily and effectively replace manual inspection, discover problem changes, solve equipment hidden dangers, achieve predictive maintenance, and avoid losses caused by unplanned downtime.

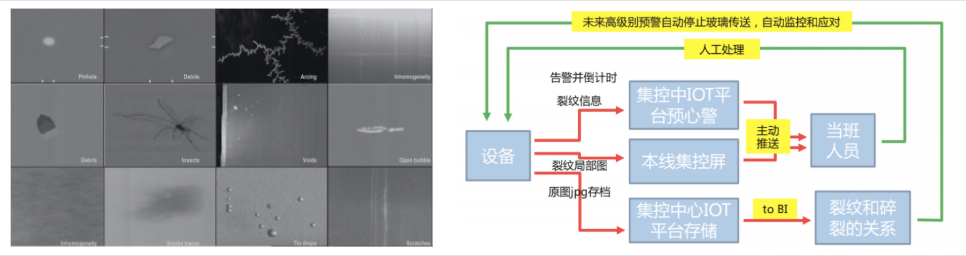

2. Machine vision quality inspection (application core: 5G indoor ultra-high bandwidth)

There are many intelligent production workshops in the manufacturing industry that have visual quality inspection processes. The quality inspection of their products relies on manual labor and experience, and there are problems such as low standardization, high labor costs, and susceptibility to subjective factors, low overall efficiency, low accuracy, and difficulty in tracing defects. For example, mobile phone screen defect detection, with a resolution of 1 billion pixels, and industrial cameras with a file size of over 1GB per photo, it is currently difficult to support the bandwidth and reliability of data transmission through existing networks such as 4G. However, uploading thumbnails in the traditional sense can lead to distortion of defect information.

Through the deployment of the built-in 5G communication module industrial camera and edge computing gateway in the production line, the super bandwidth of 5G network technology (supporting a downlink rate of 20Gb/s and an uplink rate of 10Gb/s), and low latency and high reliability (achieving a delay of 0.5~1ms and a reliability of more than 99.999%) can be used to upload file data in seconds, and upload pictures or video information of the items to be detected through high-definition industrial cameras to the cloud, Conduct cross regional and cross network big data aggregation and horizontal comparative analysis to achieve high-precision quality detection, real-time defect identification, and automatic sorting. At the same time, it can effectively record the defects of detected items, provide data analysis basis for tracing the causes of defects, and support decision-making for improving production efficiency and product quality.

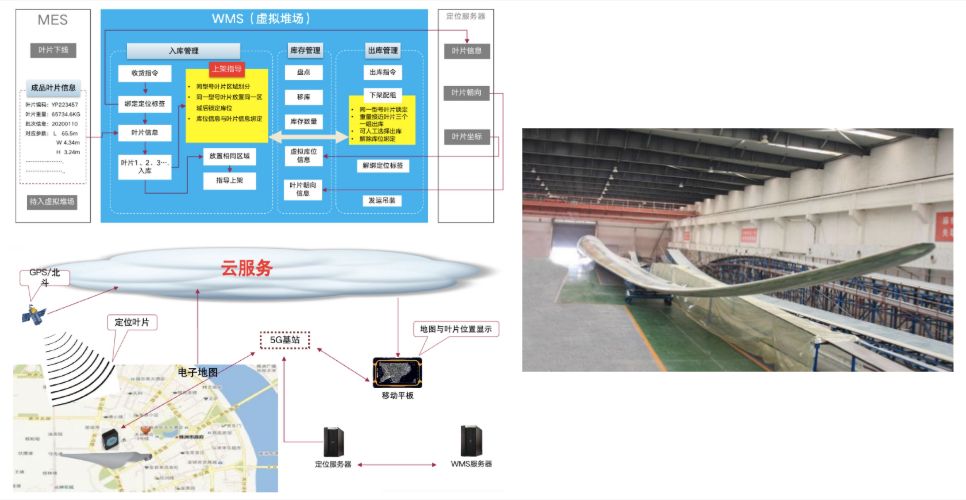

3. Enterprise asset deployment and warehouse management (application core: 5G indoor precise positioning)

Indoor positioning is a common demand in the industrial field, such as indoor large-scale three-dimensional warehouses, which need to accurately locate and store goods based on order and product specifications information, achieve forklift scheduling and route planning, and efficiently complete timely product receipt and shipment. In indoor environments, there are also common problems such as high equipment density, short distance between equipment, and unstable signals due to obstruction, which require high equipment positioning accuracy and signal stability.

At present, indoor positioning is basically divided into three parts: Bluetooth, laser, and UWB. The large bandwidth characteristics brought by the use of new encoding modulation and large-scale antenna arrays in 5G are conducive to parameter estimation and provide support for high-precision distance measurement; Large scale antenna technology, 5G base stations can achieve 128 antenna arrays, providing support for high-precision angle measurement. In addition, 5G will achieve Ultra Dense Networking (UDN), where user signals can be received by multiple base stations simultaneously, which will facilitate the collaboration of multiple base stations to achieve high-precision positioning. Therefore, 5G may be a better alternative to Bluetooth, laser, and UWB in indoor precise positioning. By deploying a large number of 5G low-power positioning tags, indoor precise positioning can be efficiently and cost-effectively achieved, meeting the needs of enterprise asset deployment and warehouse management scenarios.

4. Massive connection of production line equipment (application core: 5G high-density concurrent connection)

Taking the production park of an enterprise as an example, if multiple production lines are produced in parallel, there will be hundreds or even thousands of connected devices working simultaneously, and the requirements for transmission speed, latency, and so on will also vary. For this industrial grade high-density concurrent connection scenario, it can provide over 5000 real-time working industry terminals with the ability to simultaneously access 5G networks per thousand square meters of coverage. Whether it is equipment for real-time scheduling of production resources or busy assembly or testing machines on the production line, they can connect to the 5G network without blocking, truly achieving a fully connected intelligent enterprise;

Taking the automotive production line as an example, each engine is engraved with a number and barcode, and each process is verified by sensors for data, and all information from the product launch to packaging is recorded. By incorporating 5G NB-IOT technology, manual intervention can be reduced, production data can be collected in a timely manner, production plans can be arranged reasonably, and production line personnel can be significantly reduced. The automation rate of operations and automatic error correction and prevention capabilities will be greatly improved, and per capita output efficiency will also be significantly improved.

In 2019, SiE Information and a vehicle manufacturing enterprise in Guangzhou launched a project cooperation on remote monitoring and maintenance of equipment based on 5G, helping customers achieve safety monitoring and equipment health management of constant temperature and humidity motor rooms in the factory area through cooperation. After importing the SiE Industrial Internet solution, the SiE Industrial bracelet is deployed inside the daily enclosed fan room. Sensors monitor the motor operation status, and the collected equipment operation data is uploaded to the cloud through a 5G wireless signal gateway, combined with algorithms for analysis and diagnosis. Users can open their mobile mini programs or WEB terminals to view status and receive alarm information in any situation. Due to the high bandwidth, low latency, wide connection, and high security characteristics of 5G, it can solve the problems of multiple device access and protocol conversion. In data retrieval and data collection applications, it greatly improves data reliability, reduces data packet loss rate, is more stable, and data transmission is more reliable, making it easy to achieve data synchronization processing for multiple groups of terminals. Finally, daily maintenance and inspection of equipment in enclosed machine rooms with special environmental requirements (constant temperature and humidity) will be carried out without stopping the machine and affecting production. The operation status of the motor will be remotely monitored in real-time for 7 * 24 hours, and potential faults will be promptly warned to avoid unplanned shutdowns. With the support of 5G technology, customers will be assisted in achieving lean operation management of equipment in the factory area.

In 2019, SiE Information collaborated with a glass manufacturer to launch a machine vision glass defect monitoring project based on 5G+AI. The technical characteristics of 5G network with ultra large bandwidth provide imaging conditions for high-precision measurement and defect detection, helping to achieve image processing with large dimensions (billion pixels and above) and high resolution (0. x micrometer resolution), as well as high-level imaging scheme design. The solution not only leverages the advantages of image feature extraction algorithms, but also combines the performance advantages of AI algorithms for defect classification. Through AI+computer vision technology, the image is structurally analyzed, and AI model algorithms are used for real-time inference. Based on the analysis results, corresponding instructions and reports are output, ultimately achieving efficient and high-precision quality and defect recognition, Assist customers in establishing defect detection plans and control standards based on machine vision equipment, solving a series of problems such as low manual quality inspection efficiency, missed inspections, and difficulty in recording and tracing defect results in glass defect monitoring.

The project utilizes the high-precision measurement and positioning capabilities supported by 5G base stations, combined with the ultra wideband data transmission capabilities of 5G, to customize a planning solution for the intelligent storage management of a wind turbine blade virtual storage yard for a new material technology enterprise. The blade positioning management system consists of GPS positioning labels, positioning managers, PC and mobile devices. The GPS positioning labels collect and output position coordinates to the positioning server according to application requirements, and then the positioning server distributes the information to the WMS server, PC, and mobile devices. When searching for vacancies and blades, the warehouse location number is received from the WMS server and clearly displayed on the map to guide on-site personnel to quickly reach the predetermined location. Through the virtual storage yard interface and corresponding instructions, guide employees to quickly and accurately achieve blade positioning, information binding, associated grouping, shelving and unloading, warehousing and outbound operations, and assist customers in efficiently achieving intelligent transformation and upgrading of wind turbine blade storage management.